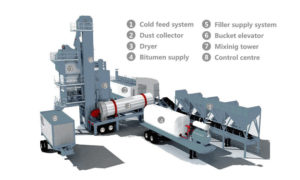

The Power 160 ton/hour mobile asphalt plant is suitable for the production of hot asphalt for big scale road projects.

HIGH LEVEL MOBILITY

160 ton/hour mobile asphalt plant; With its special mobile design on the chassis, it offers fast installation in road projects. Every equipment, from tanks to mixing tower, is sent on a mobile chassis with its installations and electrical connections ready.

PRODUCTION IN EUROPEAN STANDARDS

We know the importance of your asphalt plant working with minimum malfunction and maximum efficiency. For this reason, we use parts of global scale brands and pass them through quality control processes at every stage of production. We don’t take any plant to the field without testing it from our factory.

HIGH PERFORMANCE

Small details reduce your asphalt plant performance. Plant equipment is designed according to %5 humidity. The dryer, filter, screen and mixer are designed to work at maximum capacity.We do our work depending on the geography where each plant operates.

LOW OPERATION AND MAINTENANCE COSTS

Asphalt plant operation and maintenance costs are very important for you to compete with the market. You will reduce your asphalt production costs with low fuel consumption, heat and wear resistant steel parts, and our user-friendly software.

ECO FRIENDLY AND LONG LASTING FILTER TECHNOLOGY

Our reverse air flow bag filter technology works within the limits where environmental rules are required. With its pre-separator providing %50 filtering ease, 180-degree resistant metaaramid bags, and a piston-free and valveless cleaning system, you will have a long-lasting and minimally-maintenance filter.

POWERCONTROL AUTOMATION SYSTEM

With the power control automation system, you can connect the asphalt plant to our factory from every construction site with internet, you can make fault detection and software update. With its multi-language support, user-friendly interface and security measures, you will not interrupt asphalt production.

AFTER SALES SERVICE, WARRANTY AND SPARE PARTS

With over 40 years of manufacturing experience, we know the importance of after-sales support. Our expert team provides 24/7 service, and our company keeps critical parts in stock. With our 2-year plant warranty and after-sales support, your construction site will continue on its way.

ADDITIONAL EQUIPMENT

There may be equipment requirements for the production of different types of asphalt. Power asphalt plant is designed in such a way that additives (such as fiber additives, modified bitumen, foam asphalt) and recycling asphalt unit can be added.

REDUCE YOUR CONCRETE FOUNDATION COSTS

Your concrete costs are reduced with the steel legs we manufacture optionally for the tower and other equipment.

Français

Français  Русский

Русский  العربية

العربية  Türkçe

Türkçe