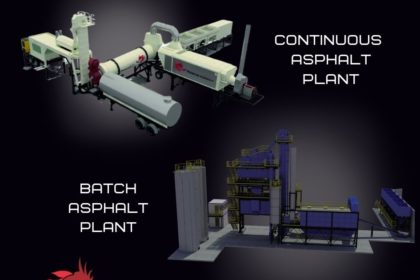

Continuous and Batch asphalt plants are plants that produce hot asphalt by mixing aggregate, bitumen and filler at certain rates. On the other hand, the batch asphalt plant produces asphalt by completing the process of the hot asphalt mixture in a certain period. They have similar plant equipment and similar processes in terms of working principle, but there are some differences between the equipment.

When it is decided to purchase an asphalt plant for the investor, the investor should be informed about the selection of the asphalt plant type and the selection should be made accordingly.

So what are the differences between continuous and batch asphalt plants?

- It has a vibrating screen that separates the hot aggregate coming out of the dryer into its fractions.

- It has a hot aggregate bin that stores the fractionated aggregate under the screen and feeds the aggregate bin in accordance with the prescription.

- It has bitumen, filler and aggregate scales. Mass weighing is done.

- The mixer mixes in a certain period, that is, it has a batch mixer.

- Maintenance and operating costs are higher than the continuous asphalt plant.

- Its usage requires more expertise than a continuous asphalt plant.

- Generally, the batch asphalt plant is used in countries such as Europe, Ukraine, Russia, Kazakhstan, Uzbekistan, Egypt, Iraq, Turkmenistan and Israel.

- It is more expensive than a continuous asphalt plant.

- Its installation takes longer than a continuous asphalt plant.

- Logistics costs are more expensive than a continuous asphalt plant.

- It doesn’t have a vibrating screen.

- It doesn’t have an under screen hot aggregate bin.

- It doesn’t have an aggregate scale. Aggregate is fed volumetrically by dosage conveyors in the feeding bins in accordance with the recipe.

- There is no filler scale. Filler is dosed volumetrically with the screw conveyors under the filter.

- There is no bitumen scale. Bitumen is dosed volumetrically by pump in accordance with the prescription.

- The mixer prepares the hot asphalt mixture by continuously mixing the mixture and discharging it directly.

- Its usage is much easier than a batch type asphalt plant.

- Maintenance and operating costs are cheaper than batch asphalt plants.

- Generally, continuous type asphalt plant is used in countries such as Senegal, Tunisia, Algeria, Morocco, Congo, Ivory Coast and Mauritania.

- It is more affordable than a batch asphalt plant.

- Its installation takes a shorter time than the batch type asphalt plant.

- Logistics costs are cheaper than batch asphalt plant.

Batch Type Asphalt Plant; when prescription flexibility, working with different customers, and the use of special formulas are required;

Continuous Asphalt Plant; It should be preferred when low operating costs and continuous production are desired.

When we examine both asphalt plant types in general, they have advantages and disadvantages compared to each other. Power asphalt plants use world-renowned components in both types and produce with its experienced staff without compromising on qualityIt is among the leading companies in the world in terms of price / performance. You can contact us and get an asphalt plant offer so that we can offer you the most accurate options.

Français

Français  Русский

Русский  العربية

العربية  Türkçe

Türkçe